The Case For Factory-Installed Temperature Probes

Temperature Monitoring

Temperature monitoring is one of the most critical steps in keeping your vaccines safe. For this reason, the Centers for Disease Control and Prevention (CDC) recommends the use of digital data loggers, and not other temperature monitoring devices such as alcohol/mercury thermometers or chart recorders.

Medical refrigerators often come with a data logger connected to a detachable glycol-encased probe installed on the unit. The probe’s cable connected to the data logger is carefully mounted so that the interior of the refrigerator is perfectly insulated.

Since having data loggers factory-installed on medical refrigerators is optional for many products, many consumers opt to buy medical refrigerators without one to save on cost. To accommodate the need of monitoring temperature of vaccines, these consumers buy aftermarket data loggers with temperature probes and try to install these data loggers by themselves. However, instead of having the probe’s cable go through the back to be perfectly sealed (as is the case with factory installations), the only choice customers have is to let the cable go through the door.

The Drawbacks of User-Installed Monitoring Probes

No matter how thin the cable is, it always leaves a gap between your refrigerator’s door and the cabinet. This gap allows warm air to get inside the refrigerator, which can increase and destabilize the temperature. Over time, this can also lead to the door gasket becoming permanently deformed.

Additional Resources:

How To Select a Medical Refrigerator

Safe Vaccine Handling

Protection During Power Outages

Options For Temperature Monitoring

FAQs About Medical Refrigeration

Temperature Conversion Chart

Accucold Resources

Studies & Experiments:

Comparing Medical & Dorm-Style Refrigerators

Chart Recorders Vs. Data Loggers

The Importance of Glycol

The Case For Factory-Installed Probes

Accucold Refrigeration:

Performance Series Packages

Vaccine Series Refrigeration

Medical & Laboratory Refrigerators

Medical & Laboratory Freezers

Low Temperature Freezers

Interior Locking Compartments

Calibrating Your Accucold Equipment

Figure 1. Air gap between refrigerator’s door gasket and cabinet

Many medical products, especially vaccines, are very sensitive to temperature changes. The CDC recommends refrigerated vaccines to be stored at temperatures between 2℃ and 8℃ (36℉ and 46℉), while vaccines stored in the freezer should maintain temperatures between -50℃ and -15℃ (-58℉ and 5℉). Allowing temperature to rise or fall outside of these ranges risks damaging the vaccines inside. Knowing this, many consumers use tape to seal the gap. However, this only reduces the amount of hot air coming into the refrigerators, but does not completely prevent it. Moreover, this requires consumers to remove the tape every time they want to open the door, which can be cumbersome to a busy staff.

In addition to the effect on the temperature, the air gap also makes the compressor of the refrigerator work harder in order to compensate for the heat loss. As a result, it increases energy consumption and fatigues the compressor.

Based on this discussion, a factory-installed probe, in theory, offers better long-term results than a probe manually inserted by a consumer. In order to determine whether this is true, FSI’s AccuCold staff conducted an experiment designed to demonstrate the difference between using factory-installed and manually-installed probes, both visually and in their impact on the refrigerators.

Experiment:

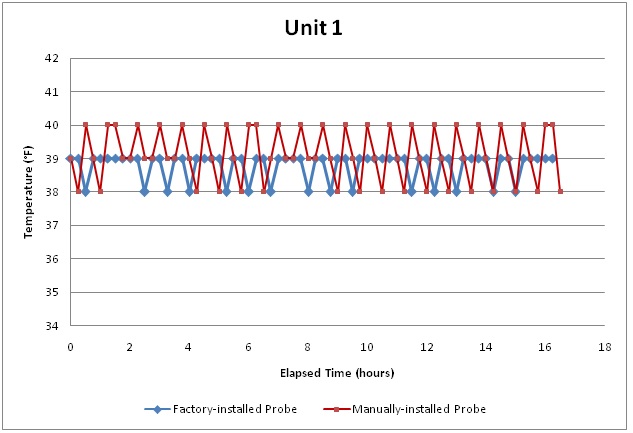

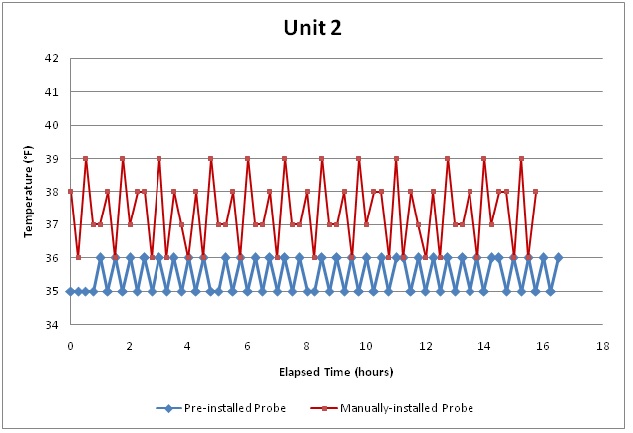

This experiment included two slightly different Accucold FF7L refrigerators. Unit 1 was equipped with an aluminum thermal stabilization system, while unit 2 was equipped with a galvanized steel stabilization system. Each refrigerator was lightly loaded with two gel packs and had its thermostat set at 38℉.

For unit 1, the probe’s cable was connected to the data logger through the door. For unit 2, the factory-installed probe within the refrigerator was used, meaning the probe did not have to go through the door. This experiment was run five times to achieve consistent results.

After five runs, the setups of the two units were reversed. The manually-installed probe of unit 1 was removed and replaced by the factory-installed probe. On unit 2, the factory-installed probe was replaced by a cable that went through the door to simulate how the typical end user would connect the probe to the data logger. The two refrigerators were then again run five times to ensure consistency.

Two Accucold digital data loggers with glycol-encased probes were used to obtain accurate temperature measurements.

Results:

Only two from the first and last five runs from each refrigerator were shown below as the data collected is very consistent. Under approximately the same ambient temperature, two sets of data from the same refrigerator were combined in order to show the difference between the two types of probes.

In the graph above, the red line represents the temperatures recorded when a probe was installed through the door. The blue line represent the temperatures recorded with a factory-installed probe. As can be seen, the temperatures inside the refrigerator first fluctuated between 38 and 40℉, as the probe left an air gap between the gasket and the cabinet. However, after that probe was removed and the factory-installed probe was used instead (thus eliminating the air gap), the temperature showed significant improvement. The temperature, as can be seen, now stayed stable between 38 and 39℉.

With a galvanized steel thermal stabilization system, this second refrigerator experienced more effects from the air gap created by the probe’s cable. Similar to the previous graph, the blue line represents temperature measurements from the factory-installed probe on the unit, whereas the red line represents temperature measurements from a manually-installed probe. The experiment started out with a factory-installed probe being used to collect temperature measurements. In blue, the temperature proves to be very stable as it stays between 35 and 36℉. After 5 runs, the factory-installed probe was replaced by a probe connected through the door to measure the temperature. The temperature this time fluctuated more frequently and over a 3 degree range from 36 to 39℉, which is a not a good condition for vaccine storage.

Conclusion:

As our experiment shows, a manually-installed probe not only raises but also destabilizes the temperature inside a refrigerator. Different types of refrigerators will experience different degree of impact, varying from 1 to 5 degrees higher than usual. Using a factory-installed probe is better for vaccine storage as well as for the refrigerator itself since it helps the refrigerator run more efficiently. Therefore, buying a refrigerator with a data logger factory-installed, even though it seems more expensive at first, would end up saving you more money in the long run.

References:

Centers for Disease Control and Prevention. "Vaccine Storage & Handling Toolkit." June 2016. 15 July 2016